Soundproof Windows Designed & Manufactured in New York City

Soundproof Windows Designed & Manufactured in New York City

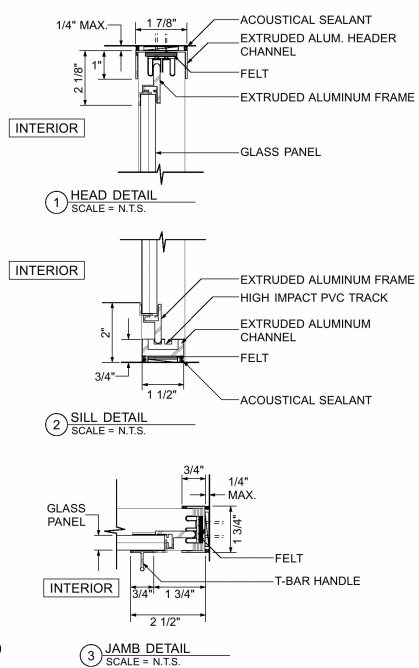

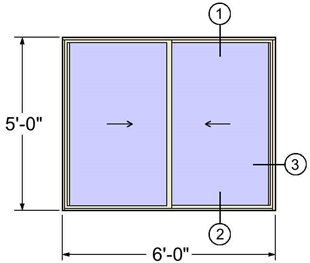

The Style #11 window consists of two (2) full-height horizontally sliding/lift-out framed glass panels. The frame depth is 2″.

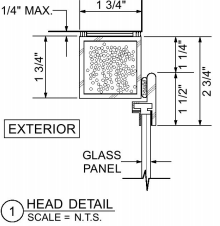

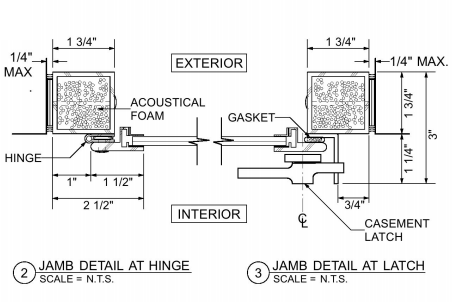

The Style #12 window consists of one (1) full-height hinged framed glass panel. The unit includes 1 3/4″ x 1 3/4″ perimeter framing, full-length stainless steel hinge and two casement latches with catches for the hinged panel. The panel can be hinged on either the left or the right side. The frame depth for this unit is 1 3/4″ deep.

The Style #12 window consists of one (1) full-height hinged framed glass panel. The unit includes 1 3/4″ x 1 3/4″ perimeter framing, full-length stainless steel hinge and two casement latches with catches for the hinged panel. The panel can be hinged on either the left or the right side. The frame depth for this unit is 1 3/4″ deep.

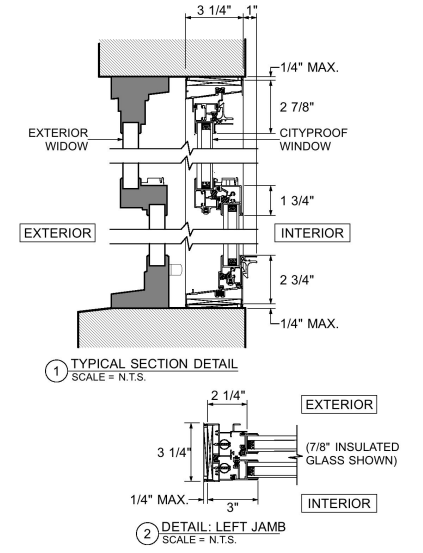

The Style #14 window is a double-hung, tilt-sash interior window with two (2) vertically sliding, framed glass panels. The frame depth for this unit style is 3 1/4″.

The Style #14 window is a double-hung, tilt-sash interior window with two (2) vertically sliding, framed glass panels. The frame depth for this unit style is 3 1/4″.

The Style #15 window consists of three (3) full-height, horizontally sliding / lift-out, framed glass panels. The frame depth for this unit style is 2″.

The Style #15 window consists of three (3) full-height, horizontally sliding / lift-out, framed glass panels. The frame depth for this unit style is 2″.